Why MAINTelligence™?

MAINTelligence™ combines comprehensive mobile asset health inspections, integrated condition monitoring, powerful AI-based diagnostics and asset management to form the world’s most complete APM solution. We also offer the industry’s most proven, data-driven solution to reduce the risk of equipment failure along with lower maintenance and operating costs for a more positive bottom line.

How MAINTelligence™ Works For You

MAINTelligence™: The 360 solution.

Intuitive and Powerful

See all of your maintenance and reliability data with a single mouse click. MAINTelligence™ features an intuitive user interface for fast and seamless access to daily scheduling, work management, and reporting tools. Find assets quickly thanks to a combination of hierarchical and list views for maximum utilization. The result: significant reduction in start-up, implementation and training costs.

A Reliability-Focused CMMS

MAINTelligence™ is the ultimate management tool for predictive and inspection based maintenance data, along with standard corrective and preventive maintenance work orders by collecting costs and allocating resources with a focus on reliability.

Reliability Tools and Features

The tools you need to plan, control, and monitor all of your maintenance-based expenditures. MAINTelligence™ ensures accurate and timely maintenance tracking, cost-effective inventory control, tool crib and contractor management, root cause failure analysis, and much more…

Maximize Plant Asset Usage

Maximize asset usage and minimize maintenance costs with real-time reports and centralized data collection.

- Track equipment, components, their systems & locations.

- Manage repairable spares, components, and sub-assemblies through their entire lifecycle from acquisition and installation through repair cycles, and inevitable replacement.

- Customize asset information with user-defined fields for any class of facility, equipment or component.

- Manually or automatically record meter data points for tracking usage, mileage, etc. Data points can be automatically collected and transferred into the MAINTelligence™ –compatible OSIsoft PI interface data via historian software packages such as OSIsoft PI.

- Increase efficiency and accuracy by utilizing barcodes and NFC tags for asset identification.

- Track extensive asset information: criticality, status, manufacturer, service and support contacts, warranty information, nameplate data, and so much more!

- Track asset work histories, operational event logs, current condition status and costs.

Explore MAINTelligence™ features

click on each title to reveal the extended descriptions

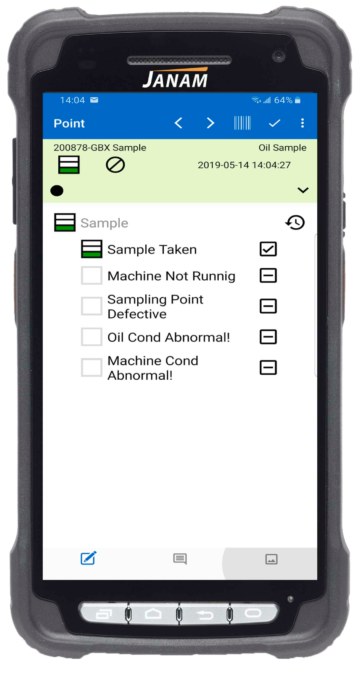

Collect

MAINTelligence™ is the only system you need to build a comprehensive machine condition based maintenance program. Vibration analysis, lubricant analysis, thermography, ultrasonic analysis, motor monitoring. It’s all here. Data access interfaces are available for a wide variety of instruments, laboratories and systems. Proven diagnostic capability adds automated intelligent analysis to your predictive maintenance program.

MAINTelligence™’s great advantage is that it not only has all major monitoring technologies but also that the data is in one single database. The same database that is available for full-featured preventative maintenance capabilities, incorporating both equipment inspection data and diagnostics. The result— MAINTelligence™ is a truly integrated maintenance information management system.

Analyze

MAINTelligence™ analyzes data from multiple disciplines simultaneously, allowing more than one monitoring methodology to be used to confirm the diagnosis of the machine’s condition.

- The Condition Assessment module can analyze data from multiple disciplines simultaneously—allowing more than one monitoring methodology to be used to confirm the diagnosis of the machine’s condition. The analysis generated is stored as a Condition Assessment result in MAINTelligence™.

- Condition Assessment results automatically trigger work orders and/or generate reports.

- Includes comprehensive alarming capabilities featuring multiple alarm trigger types and an infinite combination of alarm to data values.

- The MAINTelligence™ graphing package allows you to analyze your data and view it in the most efficient way possible, customizable to your needs.

Schedule

Staying on schedule has never been easier.

MAINTelligence™ is designed around SmartSchedule™, a powerful dynamic scheduling system that can create and administer work orders based on preventive, inspection and condition-based maintenance information. MAINTelligence™ auto-generates work orders and modifies maintenance schedules based on alarms or knowledge-based diagnostics. Maintenance schedules reflect changes in your plant environment if data exceeds controlled parameters for seamless workflow optimization.

Scheduling Flexibility

- Control the scheduling of Preventive Maintenance tasks for any of the facility, equipment and component items in your database.

- Group tasks together in a “task route”, and/or schedule as a single item.

- Numerous scheduling options available to trigger tasks and work order generation.

- Schedule by calendar, both fixed and elapsed dates.

- Schedule by meters, such as: Operating hours, mileage, production counts, etc.

- Schedule by equipment condition, alarms or knowledge-based diagnostics, and operations and production schedules.

- Opportunistic scheduling (based on machinery availability).

Generate Work

Auto-Generate Work Orders based on PM Data

PdM procedures are auto-generated in MAINTelligence™ by integrating asset basic care and predictive maintenance findings into a maintenance task schedule for results-based, proactive maintenance. Gone are the days of unused inspection data. Maintenance schedules will auto-change in real time based on inspection and measured asset condition. Easily integrated with other ERP and EAM systems, the CMMS – DMSI interface will trigger work orders as you need them.

MAINTelligence™ Is…

Intuitive and Powerful

See all of your maintenance and reliability data with a single mouse click. MAINTelligence™ features an intuitive user interface for fast and seamless access to daily scheduling, work management, and reporting tools. Find assets quickly thanks to a combination of hierarchical and list views for maximum utilization. The result: maximum utilization by the end users and a significant reduction in start-up, implementation and training costs.

Globally recognized. Customized to your needs.

For over three decades DMSI has developed practical and inexpensive solutions to the everyday problems faced by industrial, military, and transportation organizations. A leading asset performance management system both under the DMSI and OEM umbrella, our globally recognized solution is made with you in mind.

The MAINTelligence™ system allows us to offer the full benefit of our technology directly to you. Industry professionals now have access to a world-class asset performance management system that combines cutting edge technology with practical functionality and ease of use. Featuring affordable pricing, these are solutions you can’t afford to be without.

MAINTelligence™. The intelligent approach to maintenance.

Upcoming Events

MAINTelligence™ Level I – ONLINE

March 2, 2026 - March 6, 2026

Understand how to develop equipment hierarchies that support asset basic care, data accuracy, and long-term planning, along with all other Level I configuration topics.

Read moreUnlock a proven path to proactive maintenance.

Get the whitepaper to see how MAINTelligence enables consistent CBM, automated alerts, and work-order sync—plus a real-world case study.

Complete the form to download our Whitepaper.

Let’s get started.

"*" indicates required fields